Project X Loading Zone Driver Shafts

By Russ Ryden, A Golf Digest America’s 100 Best Clubfitter

Fit2Score, Dallas Fort Worth, Texas

The Project X LZ, or loading zone shaft features a linear soft zone in the middle of the shaft which is visibly reinforced with bias wraps to maintain torsional stability. This 2014 composite driver shaft from True Temper, released under the Project X brand, is made in limited numbers in the USA facility in San Diego California. I am told only 60 or 70 can be made in any given day with current staffing.

This is an interesting option now being offered by a few companies. The general golfing public has access to the shafts that are made in the tour department for the tour players. Most graphite shafts are hand rolled. As such, the care taken by the person putting the shaft together is reflected in the quality and consistency of the finished shaft. Almost every company has some highly skilled wrappers that make their prototypes. And very often, when these people are not making protos, they are making the shafts that go to the professional tour vans. These shafts are not necessarily better than the shafts made in the volume production shops, but they are free of the shaft to shaft inconsistencies found in the factory produced product. And I have seen some inconsistencies that are hard to believe from the high volume, low cost foundries, but that is another story.

The concept of the Load Zone was to create a soft midsection in the shaft. Mid soft shafts are among the most popular shaft in my fitting experience. No shaft company likes to hear a section of their shafts being discussed as soft. If you make the tip stiff and the butt stiff, the mid is soft in relation to those other two zones. In the Project X Loading Zone shaft, the soft mid section is reinforced by a material called flex lock. That is graphite fiber oriented on an angle from the length of the shaft, commonly refereed to as bias or hoop plies. This stabilizes the torque in this zone. A full discussion of the design is shown in the videoed discussion I had with Don Brown, the True Temper graphite shaft product development manager.

Radial integrity averaged 99% with a 0.6 standard deviation. These shafts can be oriented in any direction in rotating hosels. The Loading Zone shafts are counterweighted, with high balance points. A good match to the bling heavy driver heads that dominate the 2014-15 market. The GJ torque profiles were linear. The soft mid zones, stabilized with the flex lock material did not exhibit a significant drop in torque from the zones closer to the butt of the Project X Loading Zone Shafts. As shown in the averaged EI profiles, the shafts could be sorted into three distinct design groups. Sorted by flex, not illustrated, the position of the loading zone is centered across the 50, 60 and 70 g versions. Sorted by weight, the loading zone moves toward the tip and gets shorter as the stiffness increases. This is very interesting matrix of shafts for the fitter working with a client that fits into a mid soft design driver shaft. it illustrates the importance of working with a fitter that ‘knows’ the EI profiles of the shafts he works with.

This is an interview shot at the 2015 PGA merchandise show in Orlando. Don Brown is the Graphite Shaft Product Development Manger for True Temper Sports. The discussion of the Loading Zone Shafts gets technical. Many readers of this site tell me they do not understand some of the graphics and discussions in my reviews. What you see in this video is a discussion using the terms you see on this shaft review site. Enjoy!

FlightScope Monitoring

Project X Hand Crafted Loading Zone Driver Shafts

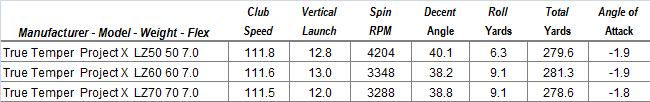

The images to the left are FlightScope acceleration charts. FlightScope radar tracks the clubhead as well as the golf ball. The head is picked up about 45 inches from impact. The FlightScope operator is presented with a large array of information to use in the club fitting process. I pay close attention to the stability and repeatably of the acceleration chart. We can see the hump in the chart, release, shifting further away from impact as the weight of the shaft increases. The combination of increased stiffness from the additional weight and the weight induced change in release manifested into a change in launch angle. The table below shows how this influenced ball flight.

The images to the left are FlightScope acceleration charts. FlightScope radar tracks the clubhead as well as the golf ball. The head is picked up about 45 inches from impact. The FlightScope operator is presented with a large array of information to use in the club fitting process. I pay close attention to the stability and repeatably of the acceleration chart. We can see the hump in the chart, release, shifting further away from impact as the weight of the shaft increases. The combination of increased stiffness from the additional weight and the weight induced change in release manifested into a change in launch angle. The table below shows how this influenced ball flight.

Weight of the shaft and weight of the club head are key components of golf club fitting. Your sweet spot, the weight that creates the most stable speed and path can only be found by a fitter equipped with shafts and heads in various weights.

In this and future reviews we will be looking at deflection of the shaft derived from the EI profile. By looking at tip loading we see how the shaft bends from the weight of the head magnified by its speed and acceleration. The butt loading deflection shows how the shaft bends from the force applied at the handle. The 50 gram shafts are significantly easier to load from the butt. The 60 and 70 have much the same butt loading character, differing more at the tip, where the 70 gram shafts, designed for higher speeds have more tip stiffness and a lower launching propensity.

In this and future reviews we will be looking at deflection of the shaft derived from the EI profile. By looking at tip loading we see how the shaft bends from the weight of the head magnified by its speed and acceleration. The butt loading deflection shows how the shaft bends from the force applied at the handle. The 50 gram shafts are significantly easier to load from the butt. The 60 and 70 have much the same butt loading character, differing more at the tip, where the 70 gram shafts, designed for higher speeds have more tip stiffness and a lower launching propensity.