Loomis EPP Iron Shafts

By Russ Ryden, A Golf Digest America’s 100 Best Clubfitter

Fit2Score, Dallas Fort Worth, Texas

Graphite golf shafts are reported to have been first introduced to golf in 1973. In the early days of graphite golf shafts some of the expertise in the graphite business was in the fishing rod business. And a few of those companies entered the golf business. One of those was G. Loomis, still a prominent brand of fishing rods.

Graphite golf shafts are reported to have been first introduced to golf in 1973. In the early days of graphite golf shafts some of the expertise in the graphite business was in the fishing rod business. And a few of those companies entered the golf business. One of those was G. Loomis, still a prominent brand of fishing rods.

Jeffery Meyer began designing graphite shafts with Aldila in 1987. He went to work for Gary Loomis as Director of Engineering in 1992 and the Loomis shafts he designed quickly developed a following on the PGA Tour. The company was sold to Aldila in 1996 and Jeffery went to work for Acushnet as Director of Golf Shaft Development and was later given the responsibility of developing Titleist’s metal woods. The Loomis brand is now back in the hands of Meyer Performance Composites. Loomis shafts are back, and the brand has Jeffery and Robert Meyer at the helm. Robert, is a professional player and a former tour rep. This video is my first meeting with Jeff Meyer at the 2015 PGA Merchandise Show in Orlando. The actual discussion went long beyond 30 minutes so I cut some of is out. I knew I had met a like minded individual as the discussion got very technical.

I did measurements of both the EPP 95 and the EPP Tour models. The shafts are made for Loomis by Mitsubishi. That got my attention. What really got my attention was the use of the Mitsubishi TiNi wire in the tip of the shafts. It was introduced many years ago in the light weight Bassara Griffin. It is now used in the KuroKage Silver and KuroKage Tour driver shafts. It is a highly elastic thread woven into the tip of the shaft. In designs with similar profiles, the TiNi wrapped versions have less loss of stiffness in the tip area resulting in lower launch and spin. This is the first I have seen it used in an iron shaft.

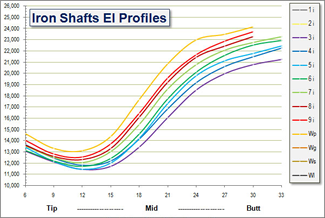

I created a process using my EI instrument that I call set certification. Every shaft in an iron set gets measured down its length in 2″ increments. The process identifies outliers, shafts that do not match the bend profiles of the rest of the set. Recent testing on graphite constant length taper sets have not been encouraging. What I have been seeing had me ready to go back to using parallel graphite shafts in iron sets. And if you knew me well you would understand just how much I abhor that idea. Knowing the Loomis shafts are made by Mitsibushi, and knowing how consistent the no longer available Fubuki AXi shaft was, I asked Jeff Meyer to send me one set of each of the EFP95’s to check. The following graphic are the set certification profiles. I LIKE what I see. If you are looking for premium graphite 95 gram iron shafts put the LOOMIS brand on your radar. These are consistent sets.

The graphics on the shaft are big and bold. If you do not like them in your face, you can simply install them label down. The back side in a pleasant solid silver completely neutral to the eye. I like it. There is no concern with orientation of these shafts, the radial consistency was 99.5% with a standard deviation of 0.1%. Summary, it does not get any better than that, these shafts are round.

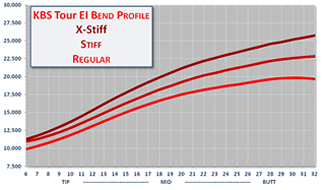

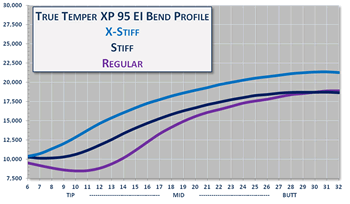

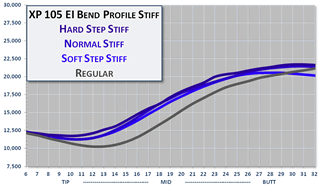

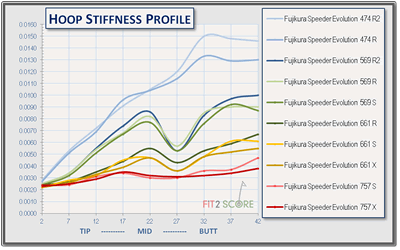

My experience measuring countless sets of iron shafts has lead me to understand that you cannot compare iron shafts by simply looking at the 6 irons as many have traditionally done. Yes, the view of a single shaft in the set is a useful way to compare shafts, but irons sets are made with 8 different shafts. And they do not necessarily have the same bend properties throughout the set. “Flighted” was the descriptive term coined years ago with the Rifle brand. True Temper now coined a new word I like, “progressive launch”. And I am now revisiting the popular iron shafts in my database and adding measurements of the longest and shortest irons in the sets. As luck would have it, the Loomis 95 and the Tour models represent the two ends of this issue and illustrate why this is important.

The Loomis EPP 95 is a mildly progressive launch design. The wedge profile is ‘straighter’ than the 3 iron shaft. I discuss this at length in the article on Parallel Shafts. Not extremely so as some sets are, but you will get a higher launch in your long irons from the Loomis EPP 95. The mid 90 gram iron shaft is a weight range I find is a great fit for the average golfer. I am told the 125 version now in production will be much the same. The torque of both models is steel like. The 95’s are slightly low balance, the Tour’s slightly high balance.

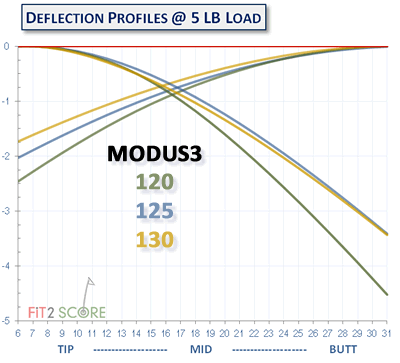

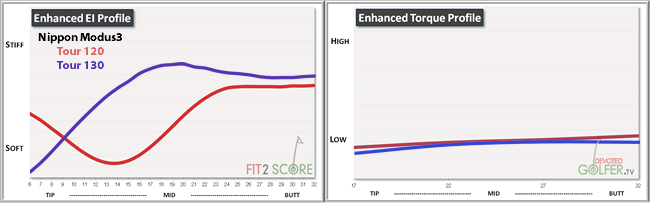

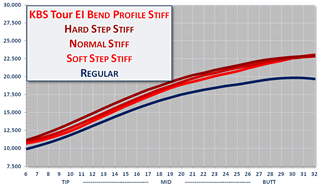

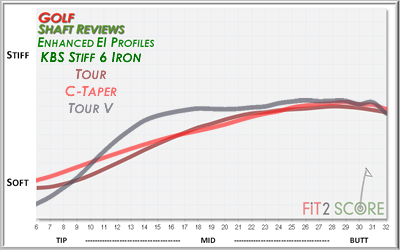

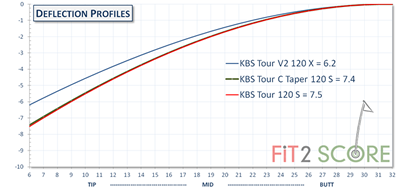

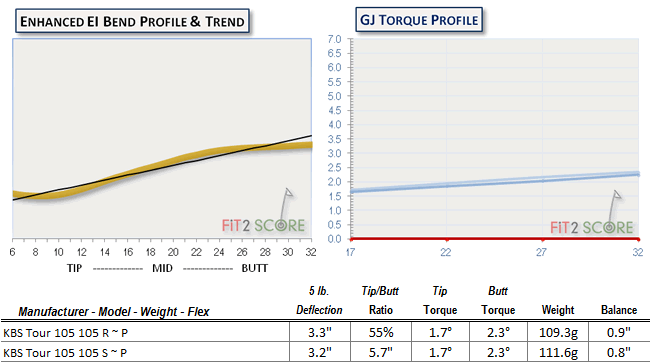

That brings us to the Tour model. It is a radical design. All of the shafts in this set have identical bend profiles. They are discrete lengths, manufactured in discrete lengths. The weight descends in the set, with the weight ranging from 109 g wedge shaft to 118 g 3 iron shaft. Jeff Meyer had a set of the 90’s Loomis iron shafts sent to him and forwarded them to Golf Shaft Reviews for a comparison. The identical bend profile design is indeed the same as the the Loomis shaft of the 90’s. The bend profiles however are quite different. The 2015 Loomis Tour profiles is similar to what we currently see in composite irons shafts. The 1990’s design bears a resemblance to the KBS Tour V’s and the Nippon Modus3 130’s.

That brings us to the Tour model. It is a radical design. All of the shafts in this set have identical bend profiles. They are discrete lengths, manufactured in discrete lengths. The weight descends in the set, with the weight ranging from 109 g wedge shaft to 118 g 3 iron shaft. Jeff Meyer had a set of the 90’s Loomis iron shafts sent to him and forwarded them to Golf Shaft Reviews for a comparison. The identical bend profile design is indeed the same as the the Loomis shaft of the 90’s. The bend profiles however are quite different. The 2015 Loomis Tour profiles is similar to what we currently see in composite irons shafts. The 1990’s design bears a resemblance to the KBS Tour V’s and the Nippon Modus3 130’s.

The idea is to create a set with a narrower butt frequency range that what is typical. I checked these with typical 3i, 6i and Pw heads at standard lengths and they do in fact exhibit that property. The butt frequency range is about half of what one would typically see. If you understand that stiffness and launch are interrelated, stiffer launching lower than softer on a good ball strike, you would then predict that the short end of the set in such a set would launch higher than a traditional build. And I am told that is indeed true.