패러랠 아이언 샤프트 vs 동일무게 테이프 샤프트

By Russ Ryden, A Golf Digest America’s 100 Best Clubfitter

Translation by Jae Chang Jo Ph.D.

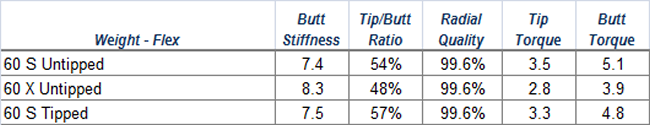

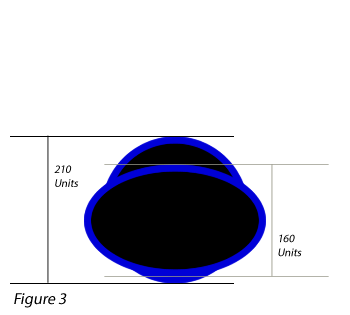

아이언 샤프트는 두 종류가 있다. 공장에서 이미 팁을 자른 것과 패러렐 샤프트이다. 유니타이즈(Unitized) 패러렐 팁 샤프트는 70년대 초반에 트루템퍼 회사에 의해 소개되었다.

이번에는 두 샤프트의 간단한 설명을 하고 EI 측정으로 논의를 한다. 만약 골퍼이면서 클럽 피터가 아니라면 샤프트의 근본적인 이해를 도울 수 있는 지식을 간략하게 설명하고자 한다. 클럽 피터이라면 패러렐 샤프트의 특성을 이해할 수 있을 것이다.

공장에서 팁트림 샤프트의 셋트 (Trimmed Iron Shaft Sets)

한 셋트의 샤프트를 공장에서 이미 길이에 맞게 자른 이용할 수있다. 셋트의 샤프트는 3, 4, 5 등으로이미 번호가 매겨져 있다. 그 셋트는 1/2 인치 증가하게 되어 있다. 7번 아이언은 8번 아이언보다 1/2 인치 길다. 아래 사진은 4번부터 웨지까지 이다.

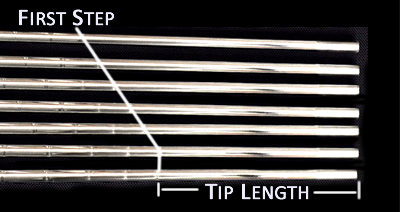

한 셋트 아이언 샤프트에서 팁부터 첫 스텝까지의 거리는 1/2 인치씩 증가하도록 되어 있다. 롱 아이언은 팁이 더 길고 짧은 아이언으로 갈수록 팁이 짧아 진다. 따라서 롱아이언은 짧은 아이언보다 부드럽다.

한 셋트 아이언 샤프트에서 팁부터 첫 스텝까지의 거리는 1/2 인치씩 증가하도록 되어 있다. 롱 아이언은 팁이 더 길고 짧은 아이언으로 갈수록 팁이 짧아 진다. 따라서 롱아이언은 짧은 아이언보다 부드럽다.

이것은 셋트내에서 강도의 동시 발생작용을 한다. 즉 롱 아이언의 헤드는 짧은 아이언 헤드보다 가볍다. 짧은 팁과 무거운 헤드의 조합하여 헤드의 무게가 무거울수록 샤프트의 팁 강도는 증가하게 된다.

대부분 공장에서 한 셋트가 길이를 조정한 아이언 셋트는 동일 무게 테이퍼(Constant Weight Tapers)라고 한다. 팁의 직경은 0.355″이며 헤드의 호젤 역시 테이퍼로 되어 있다. 테이퍼 샤프트는 팁을 자를 수 없다. 동일 무게는 모든 번호의 샤프트가 거의 동일한 무게이다. 동일 무게 샤프트는 스윙웨이트 혹은 MOI 매칭을 할 때 샤프트의 무게 중심에 대한 큰 논쟁꺼리가 되기도 한다.

모든 공장에서 팁을 자른 아이언 샤프트가 테이프는 아니며 일부는 패러렐 팁 샤프트도 있다. 대표적인 것은 NS Pro이며 .355 혹은 .370 인치의 팁도 있다.

모든 공장에서 팁을 자른 아이언 샤프트가 동일 무게 아이언 샤프트가 아닐 수도 있다. 트루 텝퍼 XP 및 Dynamic Golf Progressive 샤프트가 짧아질수록 무게는 가벼워 진다.

Parallel Iron Shafts

![ParallelSetBlanks]()

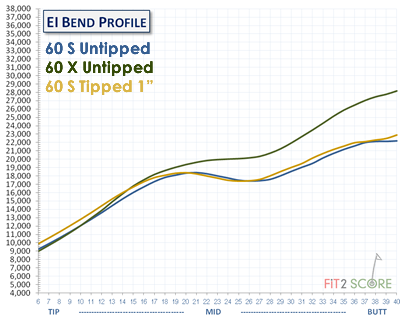

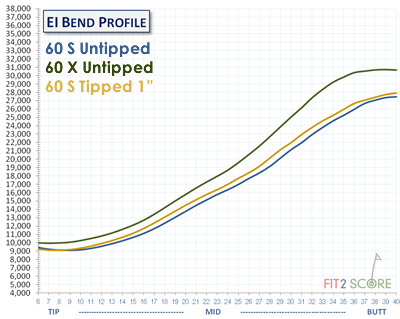

패러랠(parallel) 아이언 샤프트는 공장에서 단일 길이로 배달된다. 사례로 KBS Tour C Taper Lite 패러랠이 있다. 테이퍼라는 용어는 정확하게 맞는 표현은 아닌데, 패러랠 샤프트의 팁은 .370이다. 패러렐 샤프트는 아이언 번호가 증가할수록 매 번 0.5 인치 팁을 자르고 길이를 맞추기 위하여 버트 부분을 자른다.

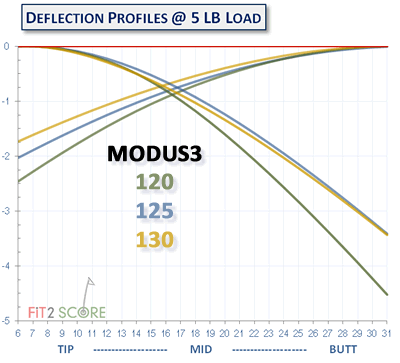

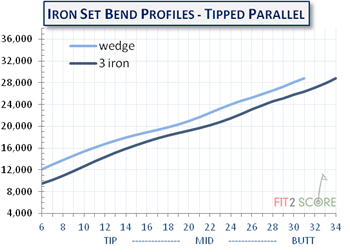

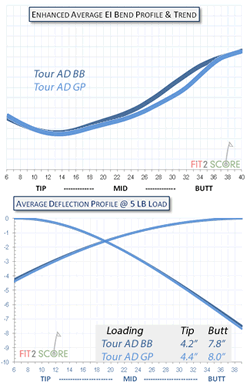

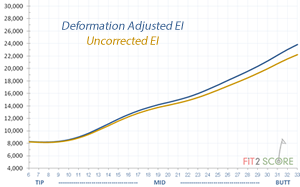

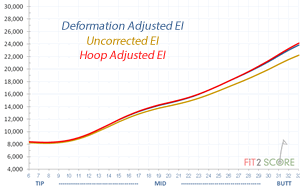

이렇게 하면 오른쪽 그림에서 보듯이 Fit2Sore 소프트웨어를 이용하여 그래프로 표현하였다.

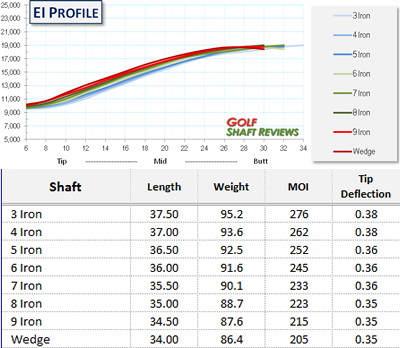

자르기 전의 샤프트의 무게는 106 그램이다. 처음 팁 커팅 3번 아이언의 무게는 95 그램이며 연속적으로 1/2 인치씩 팁을 자르면 대략 1.3 그램씩 무게가 줄어들며 웨지는 86.4 그램이 된다.

MOI 혹은 스윙 웨이트 매치된 아이언 셋트는 헤드에 추가적인 무게를 더해야 한다. 패러렐 샤프트의 동적인 무게는 3번 아이언부터 웨지까지는 25%의 무게가 줄어 든다. 그렇지만 동일 무게 샤프트(Taper 샤프트)의 무게 손실은 25%의 절반 정도이다.

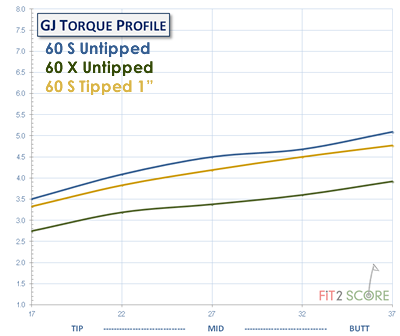

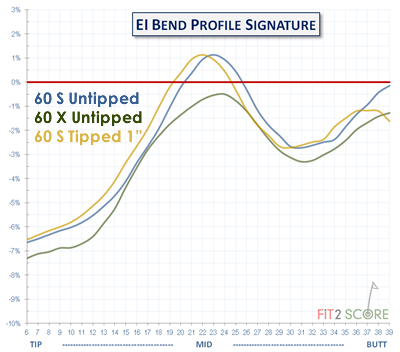

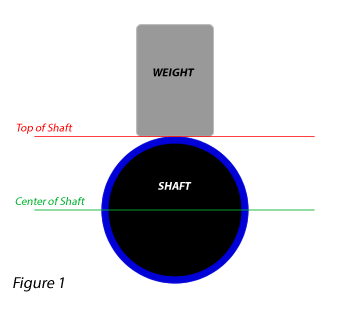

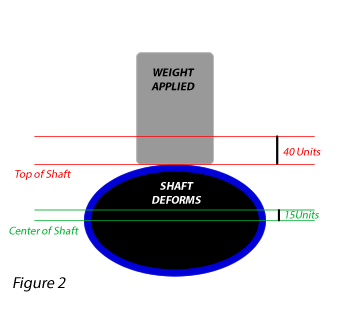

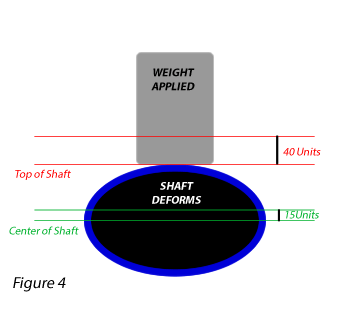

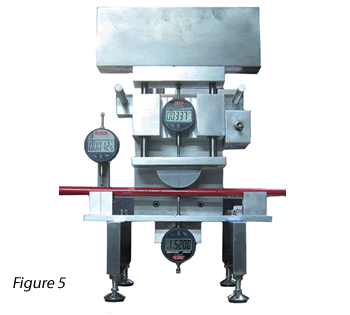

전형적인 패러렐 샤프트의 디자인을 살펴 보자. 패러렐 샤프트는 서로 다른 길이를 만들기 위하여 팁을 자르도록 디자인되었다. 이렇게 함으로서 강도는 팁부터 샤프트 중간 부분의 강도가 증가하게 된다. 팁은 샤프트에서 가장 부드러운 부분이다. 팁을 자를수록 샤프트는 강해 진다.

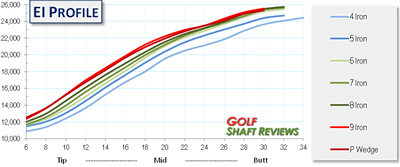

그림을 자세히 보면 샤프트의 밴드 프로화일은 변하게 된다. “Flighted” 샤프트 셋트를 분석하였다. 샤프트가 길어질수록 탄도는 높아지는 경향이 있어 짧은 아이언은 탄도가 낮아진다. 이러한 현상을 “Flighted” 혹은 점진적인 탄도라고 부른다.

KBS Tour Constant Weight Taper 샤프트와 패러렐 샤프트와 밴드 프로화일을 비교하였다. 동일 (constant) 무게 한 셋트에서는 일정하게 강도가 증가하게 된다. 샤프트의 중간 부위에서 팁까지의 강도의 변화는 일정하게 된다.

이러한 관점에서 볼 때, 패러렐 샤프트로 완성된 셋트는 근본적으로 동일 무게 샤프트와 다르다. 동적인 무게의 변화는 완전히 부정적이지는 않다. “Flighted” 샤프트 셋트를 만들기 위하여 균형이 필요하다.

그렉 노먼은 로얄 프레시션 Rifle에서 다른 브랜드의 동일 무게 샤프트로 바꾸었다고 듣게 되었다. 그는 오랜동안 우승이 없었다. 거의 캐디는 다시 라이플 샤프트로 회귀하자고 권고를 하였었다. 그는 연속적으로 우승을하였다. 이 이야기는 많은 것을 이해하게 되었다. 그래서 패러렐 샤프트를 Fit2Score EI 프로화일 소프트웨어를 이용하여 자세히 관찰하게 되었다. 감탄을 하게 되었는데, 전형적인 패러렐 샤프트 셋트가 바로 “Flighted”이었다.

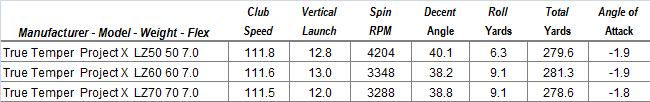

. 이전의 포스트에서 말했듯이 “모든 공장에서 팁 트림한 아이언 셋트는 동일 무게 샤프트는 아니라는 것이다. 트루템퍼 사의 XP와 다이나믹 골드 프로그레시브 셋트는 짧아질수록 가볍게 된다. “Dynamic Gold Progressive”는 패러렐 아이언 샤프트 프로화일과 비슷하다. 그림에서 무게 번호가 증가할수록 아이언 샤프트의 무게는 줄어든다. 트루템퍼의 XP 115는 무게 감소가 크지 않다. 그렇지만 어느 정도는 롱 아이언에서 웨지까지 탄도가 점차 낮아지는 경향이 있다.

. 이전의 포스트에서 말했듯이 “모든 공장에서 팁 트림한 아이언 셋트는 동일 무게 샤프트는 아니라는 것이다. 트루템퍼 사의 XP와 다이나믹 골드 프로그레시브 셋트는 짧아질수록 가볍게 된다. “Dynamic Gold Progressive”는 패러렐 아이언 샤프트 프로화일과 비슷하다. 그림에서 무게 번호가 증가할수록 아이언 샤프트의 무게는 줄어든다. 트루템퍼의 XP 115는 무게 감소가 크지 않다. 그렇지만 어느 정도는 롱 아이언에서 웨지까지 탄도가 점차 낮아지는 경향이 있다.

아이언 샤프트의 리뷰는 과거에는 6번 아이언을 대상으로 하였는데 앞으로는 아이언 셋트를 대상으로 분석을 할 것이다.

.